Compact and easy-to-install cartridge type Stationary mechanical seal "Cartridge Master ®".The wide variety of Cartridge Mechanical Seals can be used for various fluids such as fresh water and slurries, as well as for shaft sealing devices such as chemical pumps and stirrers.

Features

Instant delivery of stock

Standard stock items are delivered immediately, contributing to the reduction of spare parts.

It is also effective for quick recovery of various seal troubles.

It is also effective for quick recovery of various seal troubles.

Static type

It is a static structure in which the spring does not come into contact with the liquid and the squareness of the sealing surface is maintained.

It is effective as a measure to extend the seal life of aging equipment and troubled equipment.

It is effective as a measure to extend the seal life of aging equipment and troubled equipment.

compact

The most compact dimensions in the industry.

□ Can be mounted on a gland packing box of 9.5 mm or more.

Non-Flushing (dead end)

The low heat generation design allows non-flushing operation of the pump in the pressure range of 0 to 0.4MPaG.

Cartridge Mechanical Seal usage example

- Anyone can install the seal, so the proficiency level of the installation work is not required. As the number of veteran workers decreases, the installation work can be done easily.

- Since it can be attached to the gland packing box, modifications to the Cartridge Mechanical Seal have been seen in many situations in response to leaks from the gland packing.

Example of introduction to chemical conversion liquid (zinc phosphate) pump

Zinc phosphate reacts with iron in the liquid and changes to iron phosphate, which crystallizes.Iron phosphate is highly adhesive and adheres everywhere.With a normal mechanical seal, it looks like the photo on the left, and malfunctions occur frequently.

By applying the diaphragm type, the seal life of 1 to 1.5 months has been greatly improved to 1.5 years.

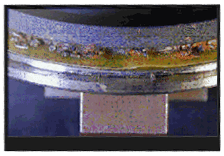

Installation example of concentrated sludge pump

The slurry contained in the concentrated sludge gets caught in the driven packing and the sliding surface, causing malfunction.

* Diaphragm type mechanical seal staples and gravel removed from the concentrated sludge pump are shut out by the diaphragm.

* Diaphragm type mechanical seal staples and gravel removed from the concentrated sludge pump are shut out by the diaphragm.

With the application of the diaphragm type, there is no malfunction and it has been operating smoothly for more than 2 years.

Installation example of flame retardant (slurry concentration 70% or more) into a pump

The slurry concentration was high, and sticking to the driven packing was the cause of malfunction.

By applying the diaphragm type, the seal life of 1 to 3 months has been greatly improved to 1 year or more.